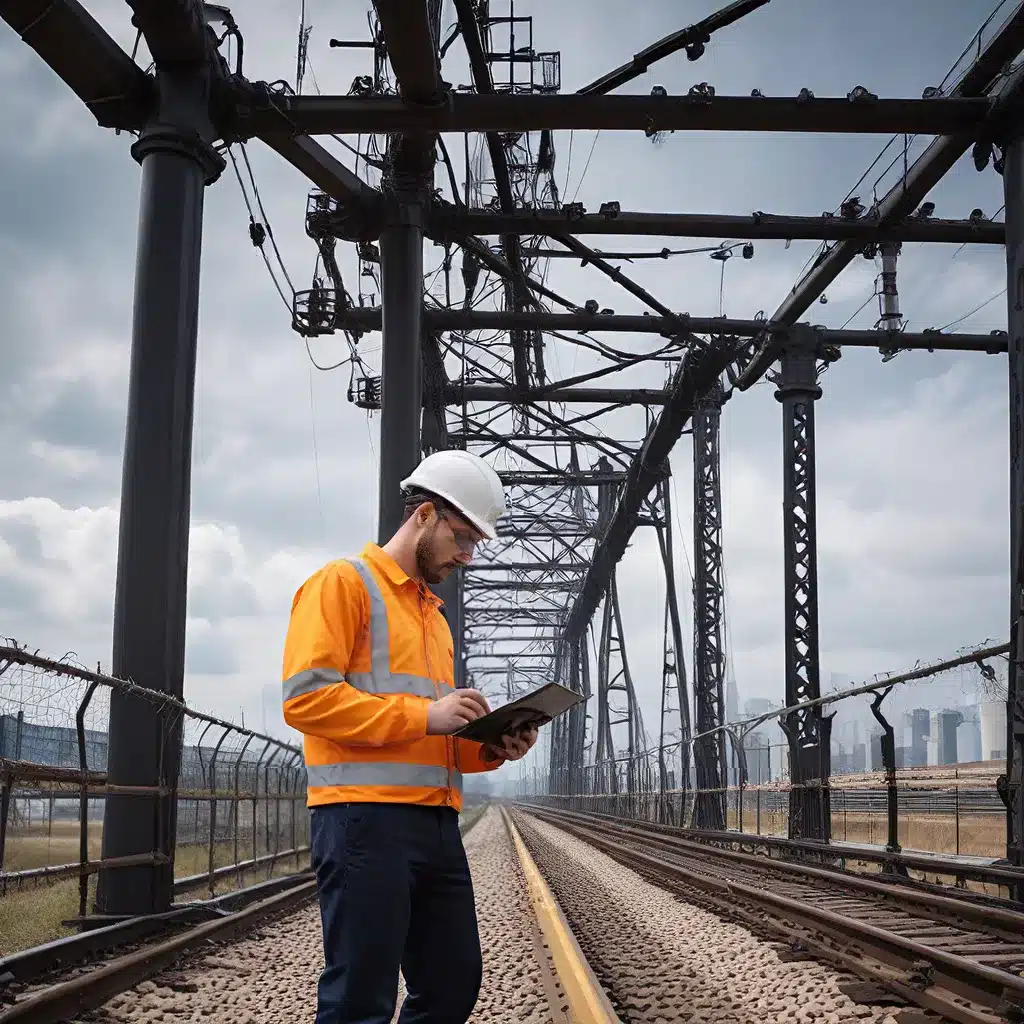

The Pivotal Role of Structural Health Monitoring (SHM) in Lifecycle Monitoring (LCM)

Structural Health Monitoring (SHM) stands at the forefront of enhancing infrastructure resilience, safety, and sustainability. Through advanced sensor technologies, data analytics, and predictive modeling, SHM provides the necessary intelligence to predict and mitigate potential structural issues. This not only ensures the longevity of our built environment but also safeguards the lives that depend on it.

The integration of SHM within the broader framework of Lifecycle Monitoring (LCM) represents a holistic approach to infrastructure management. SHM is not a standalone component but a crucial element that enhances every phase of the infrastructure lifecycle, from design and construction to operation and decommissioning. By embedding SHM strategies and technologies from the outset, LCM ensures that infrastructure projects are not only designed for immediate needs but are also prepared for long-term challenges.

Sensor-Networks.org explores the transformative potential of SHM and its role in creating resilient, sustainable infrastructure that can withstand the tests of time and nature.

Transforming Structural Health Monitoring: Innovations and Advancements

The path of SHM technologies has been one of constant evolution and innovation. From the early days of manual inspections and basic monitoring to today’s sophisticated systems, SHM has grown in leaps and bounds.

Wireless and Embedded Sensor Networks: The advent of wireless and embedded sensor networks marked a significant technological breakthrough in SHM. These sensors, capable of monitoring a myriad of parameters such as vibrations, strains, and environmental conditions, are now seamlessly integrated into the very skeleton of structures. They provide continuous real-time data, enabling proactive maintenance and significantly enhancing structural safety.

Drone Inspections: Drone inspections have also revolutionized SHM by offering a bird’s-eye view of hard-to-reach areas, delivering high-resolution imagery and data without the need for scaffolding or cranes. This not only reduces risk but also cuts down on inspection time and costs.

Digital Twins: Perhaps one of the most exciting advancements in SHM is the concept of digital twins—virtual replicas of physical assets. These dynamic models are updated in real-time with data collected from sensors, allowing engineers to simulate conditions, predict outcomes, and make informed decisions about maintenance and mitigation strategies.

These innovations have transformed SHM into a sophisticated, integral component of LCM, providing the insights necessary to maintain and enhance the resilience, safety, and sustainability of our infrastructure.

Sensor Networks and Data Acquisition: The Foundation of Structural Health Monitoring

The backbone of Structural Health Monitoring (SHM) lies in the sophistication of its sensors and the robustness of its data acquisition systems. Today’s SHM sensors are marvels of engineering, designed to capture a wide array of data types—from minute vibrations and stress changes to environmental conditions like temperature, corrosion, and humidity.

These sensors, including piezoelectric transducers, fiber optic sensors, and strain gauges, are adept at detecting early signs of deterioration or damage within structures. Integration of these sensors into infrastructure is done with precision, ensuring minimal intrusion while maximizing data accuracy.

The data collected by these sensors is then funneled through sophisticated networking and data acquisition systems. These systems not only aggregate data from various sensors across a structure but also ensure its transmission in real-time to centralized analysis platforms. The management of these large data sets is critical, with advanced software tools preprocessing, filtering, and storing the data, making it ready for analysis. This infrastructure enables the continuous monitoring of structural health, alerting engineers and maintenance teams to potential issues before they escalate.

Predictive Maintenance: Turning Data into Actionable Insights

Once data is acquired and processed, the next frontier in SHM is its analysis—turning raw data into actionable insights. Here, the role of data analytics and predictive maintenance comes into play.

Through advanced algorithms and machine learning models, SHM systems can predict the future health of infrastructure, identifying potential issues that could lead to failure if unaddressed. Artificial Intelligence (AI) and machine learning (ML) are at the forefront of this analytical process, capable of analyzing patterns in data that would be invisible to human analysts and predicting structural failures before they occur.

For instance, an AI model can learn from historical data on bridge collapses, identifying early-warning signs in current bridges that might indicate a similar risk. This predictive capacity allows for maintenance and intervention strategies to be implemented proactively, significantly reducing the risk of catastrophic failure and extending the lifespan of infrastructure assets.

One notable example of AI in action is the monitoring of the Golden Gate Bridge in San Francisco, where sensors and AI analytics work together to monitor the structure’s response to traffic and environmental stresses. By analyzing this data, the system can predict and address potential issues before they pose a significant risk, showcasing the power of SHM in maintaining iconic structures.

The Symbiotic Relationship between SHM and Lifecycle Monitoring (LCM)

The integration of Structural Health Monitoring (SHM) within the broader framework of Lifecycle Monitoring (LCM) represents a holistic approach to infrastructure management. SHM is not a standalone component but a crucial element that enhances every phase of the infrastructure lifecycle, from design and construction to operation and decommissioning.

This symbiotic relationship brings several benefits to project stakeholders:

- Improved Safety: SHM provides continuous oversight of structural health, reducing the likelihood of accidents and ensuring the well-being of the public.

- Cost Savings: Early detection of potential issues allows for interventions that are both less invasive and less expensive, preventing minor problems from escalating into major expenditures.

- Extended Asset Lifespans: The extended asset lifespans resulting from effective SHM practices translate into better returns on investment for stakeholders and reduced environmental impact as the need for new construction materials and processes is diminished.

By embedding SHM strategies and technologies from the outset, LCM ensures that infrastructure projects are not only designed for immediate needs but are also prepared for long-term challenges. This integration not only maximizes the effectiveness of monitoring and maintenance efforts but also aligns with broader objectives of resilience, sustainability, and efficiency.

Case Studies: Showcasing SHM in Action

The I-395 Signature Bridge Project

The I-395 Signature Bridge project, although still under construction, offers an insightful preview into the future capabilities of Structural Health Monitoring (SHM) in enhancing infrastructure resilience and sustainability. Tasked with a 100-year design life, this ambitious project has embraced a wide array of SHM technologies to ensure its longevity and reliability.

Innovative SHM Integration: At the heart of the project’s SHM strategy are embedded corrosion sensors, GPS units for real-time structural movement tracking, triaxial accelerometers, displacement gauges, and strain gauges. An all-in-one weather station, tilt meters, and load cells for cable stay tension monitoring form a comprehensive network that provides a 360-degree view of the bridge’s structural health.

Anticipated Outcomes: While direct outcomes will fully materialize post-construction, the project is poised to set a benchmark in proactive infrastructure maintenance and sustainability. The sophisticated SHM system is expected to enable early detection of potential issues, optimize maintenance efforts, and significantly reduce the environmental impact of repair works, aligning with sustainability goals.

The Millau Viaduct, France

The Millau Viaduct in France, one of the world’s tallest bridges, has incorporated SHM technologies to monitor its response to environmental and structural stresses since its opening.

Challenges Addressed: The main challenge was managing the bridge’s response to varying environmental conditions, ensuring its stability and longevity.

SHM Solutions Implemented: A network of sensors continuously collects data on environmental impacts and structural behavior, facilitating real-time monitoring and analysis.

Outcomes Achieved: The SHM system has allowed for precise data-driven maintenance scheduling, significantly enhancing the bridge’s resilience and contributing to its sustainability by minimizing material use and maximizing efficiency.

These case studies, one prospective and one realized, showcase the transformative potential of SHM within the realm of Lifecycle Monitoring, setting the stage for future innovations in infrastructure health monitoring and maintenance.

Embracing the Future: Challenges and Trends in Structural Health Monitoring

Despite the clear benefits, the implementation of Structural Health Monitoring (SHM) faces several hurdles, including:

- Scalability: The bespoke nature of sensor networks for each project can make scalability a challenge.

- Cost: The upfront investment required for comprehensive SHM systems can be significant.

- Complexity: Technology deployment and data analysis can be complex, requiring specialized skills and infrastructure.

Looking forward, SHM technology is poised for significant advancements. Key areas of research include the development of more cost-effective, energy-efficient sensors and the integration of AI and machine learning for more sophisticated data analysis. Innovations in materials science may also lead to sensors that are easier to integrate into various types of infrastructure, enhancing scalability.

As these technologies mature, SHM is expected to become more accessible, paving the way for broader adoption and further enhancing the resilience, safety, and sustainability of our built environment.

Conclusion: Embracing the Transformative Power of Structural Health Monitoring

This exploration of Structural Health Monitoring (SHM) has highlighted its indispensable role in advancing Lifecycle Monitoring (LCM) and the creation of resilient, sustainable infrastructure. Through the integration of advanced sensors, data acquisition systems, and predictive analytics, SHM offers unparalleled insights into the health of our built environment.

The case studies of the I-395 Signature Bridge and the Millau Viaduct exemplify SHM’s potential to address challenges head-on, ensuring the longevity and reliability of critical infrastructure. As we continue to push the boundaries of innovation, the future of SHM promises even greater possibilities for safeguarding and optimizing the built environment.

By embracing the transformative power of SHM, we can build a future where our infrastructure is not just smarter and more resilient but also kinder to our planet. Join us as we explore the cutting edge of infrastructure management and unlock the full potential of Lifecycle Monitoring.

Sensor-Networks.org invites you to share your insights and experiences with LCM and SHM, as we continue to uncover the latest advancements and their impact on the built environment.