In the rapidly evolving landscape of modern supply chain management, the integration of sensor networks and Internet of Things (IoT) technologies has emerged as a transformative force, ushering in a new era of efficiency, transparency, and responsiveness. As industries across the board strive to optimize their operations and stay ahead of the competition, the strategic deployment of sensor-enabled solutions has become a critical differentiator, unlocking unprecedented levels of visibility and control throughout the entire supply chain.

Unlocking the Power of Sensor Networks in Supply Chain Management

At the heart of this revolution lies the sensor network, a robust and interconnected framework of smart devices strategically placed throughout the supply chain. These sensors, equipped with advanced capabilities to collect, analyze, and transmit critical data, are fundamentally reshaping the way businesses approach supply chain management.

Manufacturers are integrating new technologies including Internet of Things (IoT), cloud computing, and analytics and AI and machine learning into their production facilities and throughout their operations. Smart factories, equipped with these cutting-edge technologies, are able to gather and leverage real-time data from a plethora of sensors, enabling them to make informed decisions, optimize production processes, and enhance quality control like never before.

Edge computing, a crucial component of this sensor-driven ecosystem, allows for the processing of data at the point of origin, minimizing latency and reducing security risks. By empowering manufacturers to act swiftly on critical insights, edge computing enhances the overall responsiveness and resilience of the supply chain, ultimately leading to increased efficiency and productivity.

Transforming Supply Chain Visibility and Transparency

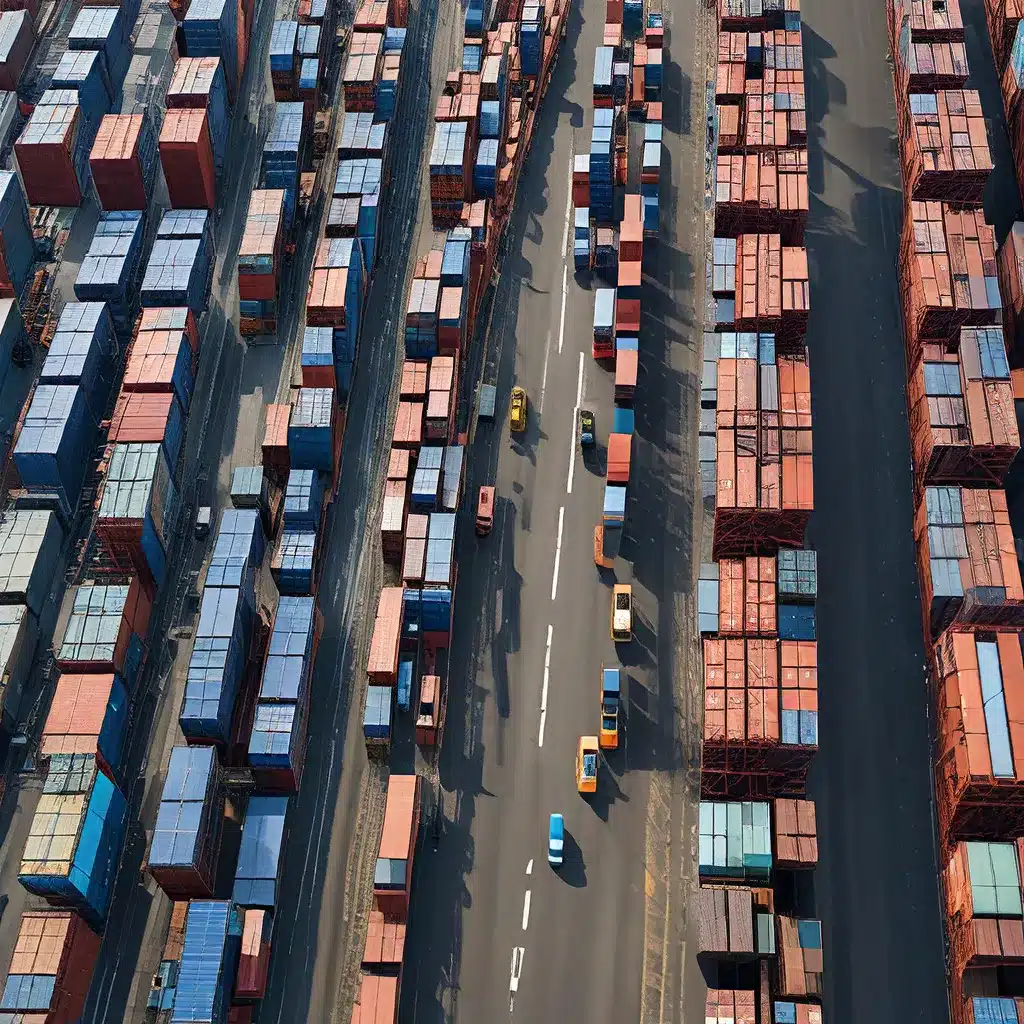

One of the most significant benefits of sensor-enabled supply chain management is the enhanced visibility it provides. IoT devices and sensors placed throughout the supply chain network collect a wealth of data, from inventory levels and production status to shipment movements and environmental conditions.

Moreover, the integration of blockchain technology is further strengthening supply chain transparency. By immutably recording all transactions and product movements, blockchain-enabled supply chains provide an auditable and tamper-resistant trail, enhancing traceability and quality control across the entire network.

Enabling Predictive Maintenance and Increased Efficiency

Sensor networks in supply chain management not only improve visibility but also drive predictive maintenance capabilities. By continuously monitoring the performance and condition of critical assets, such as machinery and vehicles, businesses can leverage machine learning and advanced analytics to anticipate and prevent potential failures before they occur.

Furthermore, the integration of sensor data with Enterprise Resource Planning (ERP) and other business management systems enables a seamless flow of information across the entire organization. This convergence of operational technology (OT) and information technology (IT) empowers businesses to make data-driven decisions, optimize production schedules, and enhance supply chain coordination.

Embracing the Industry 4.0 Transformation

The widespread adoption of sensor-enabled supply chain management aligns with the broader Industry 4.0 movement, which is redefining the manufacturing and logistics landscape. Industry 4.0, also known as the fourth industrial revolution, is characterized by the integration of advanced digital technologies, including IoT, cloud computing, artificial intelligence (AI), and machine learning, into industrial processes.

By embracing the principles of Industry 4.0, businesses can leverage the power of sensor networks to create digital twins of their supply chain operations. These virtual representations, informed by real-time sensor data, allow for simulation, optimization, and predictive modeling of supply chain processes, empowering companies to make informed decisions and adapt to changing market conditions more effectively.

Overcoming Challenges and Ensuring Cybersecurity

While the benefits of sensor-enabled supply chain management are numerous, there are also challenges that must be addressed. Ensuring the security and integrity of the vast amounts of data collected by sensor networks is of paramount importance, as the supply chain ecosystem becomes increasingly interconnected and vulnerable to cyber threats.

To mitigate these risks, businesses must adopt a holistic cybersecurity approach that encompasses both IT and OT systems, ensuring that data security and privacy are prioritized throughout the supply chain. Edge computing, encryption, and access control mechanisms play a crucial role in safeguarding the sensor-driven ecosystem, while continuous monitoring and threat detection further enhance the overall security posture.

Embracing the Future of Supply Chain Management

As the world continues to evolve at a rapid pace, the integration of sensor networks and IoT technologies in supply chain management is poised to become the cornerstone of competitiveness and resilience for businesses across a wide range of industries.

By harnessing the power of sensor-driven insights, companies can unlock new levels of efficiency, transparency, and responsiveness, positioning themselves for long-term success in the dynamic and ever-changing global marketplace. At the heart of this transformation lies the commitment to continuous innovation and the embrace of emerging technologies that will shape the future of supply chain management.

Explore the possibilities of sensor-enabled supply chain visibility and discover how your organization can leverage these transformative technologies to drive innovation, enhance customer experiences, and achieve sustainable growth on the Sensor Networks platform.