The Rise of Sensor Networks in Industrial IoT

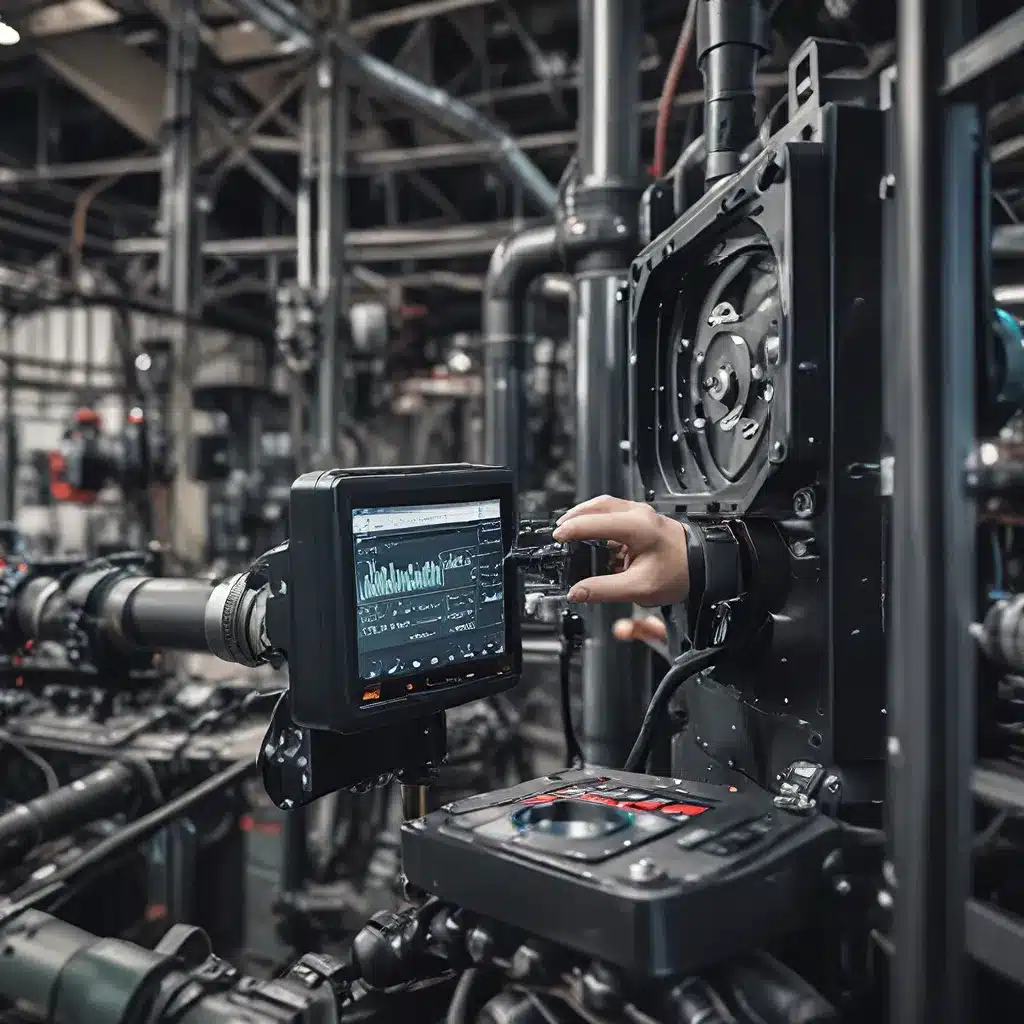

The rapid advancement of sensor technology and the Internet of Things (IoT) have revolutionized the industrial landscape, paving the way for innovative solutions in predictive maintenance. Sensor networks, comprised of interconnected devices strategically deployed across manufacturing environments, now play a crucial role in gathering real-time data, enabling data-driven decision-making and predictive analytics.

By leveraging the power of distributed sensor networks, manufacturers can gain valuable insights into the health and performance of their critical assets, such as machinery, equipment, and production lines. This proactive approach to maintenance allows them to anticipate potential failures, schedule targeted interventions, and optimize operational efficiency, ultimately reducing costly downtime and improving overall equipment effectiveness (OEE).

Sensor Network Architectures for Predictive Maintenance

The design of sensor networks for predictive maintenance in manufacturing can take various forms, each with its own advantages and considerations. Centralized architectures rely on a single, powerful control node that aggregates and processes data from a network of distributed sensors. This approach can provide a comprehensive view of the entire system, enabling advanced analytics and real-time decision-making.

On the other hand, decentralized or distributed sensor network architectures involve multiple edge nodes or gateways that independently collect, process, and analyze data from their local sensor clusters. This distributed approach can offer increased reliability, scalability, and responsiveness, as local decisions can be made closer to the point of data generation, reducing the burden on centralized systems.

| Architecture | Advantages | Considerations |

|---|---|---|

| Centralized |

|

|

| Decentralized/Distributed |

|

|

The choice between centralized and decentralized architectures often depends on the specific requirements of the manufacturing environment, such as the scale of the operation, the criticality of asset monitoring, and the available infrastructure and resources.

Sensor Network Protocols and Technologies

Sensor networks for predictive maintenance leverage a diverse range of communication protocols and enabling technologies to facilitate data transfer, device connectivity, and seamless integration with industrial systems.

Wired Protocols: Traditional wired protocols, such as Modbus, PROFINET, and EtherNet/IP, have long been the backbone of industrial automation and control systems. These protocols offer reliable and deterministic communication, making them well-suited for critical real-time applications.

Wireless Protocols: The emergence of wireless sensor network (WSN) technologies, including Wi-Fi, Bluetooth, ZigBee, and LoRaWAN, has opened up new possibilities for flexible, scalable, and cost-effective sensor deployments, especially in environments with limited infrastructure or difficult-to-access locations.

Industrial IoT Protocols: Specialized Industrial IoT (IIoT) protocols, such as OPC UA, MQTT, and AMQP, have been developed to address the unique requirements of industrial automation and edge computing applications. These protocols enable secure, reliable, and efficient data exchange between sensor nodes, edge devices, and cloud-based analytics platforms.

The selection of appropriate protocols and technologies for a sensor network in predictive maintenance depends on factors such as data throughput requirements, network range, power consumption, security considerations, and integration with existing industrial systems.

Sensor Data Analytics and Predictive Maintenance

The real power of sensor networks in predictive maintenance lies in the ability to collect, process, and analyze vast amounts of data from distributed sensors. This data can then be leveraged to predict and prevent potential equipment failures, enabling proactive maintenance strategies.

Edge Analytics: Edge computing empowers sensor nodes and gateway devices to perform local data processing, anomaly detection, and condition monitoring, reducing the need for continuous data transmission to centralized systems. This decentralized approach can offer faster response times, reduced bandwidth requirements, and enhanced privacy by keeping sensitive data closer to the source.

Cloud-based Analytics: Cloud computing platforms provide scalable, powerful, and cost-effective resources for advanced data analytics, machine learning, and predictive modeling. By integrating sensor data with historical maintenance records, asset management systems, and external data sources, cloud-based analytics can deliver comprehensive insights and optimized maintenance strategies for the entire manufacturing ecosystem.

Predictive Maintenance Algorithms: Sensor networks enable the application of various predictive maintenance algorithms, such as time-series analysis, vibration analysis, and machine learning models, to forecast equipment failures, optimize maintenance schedules, and improve asset reliability.

By seamlessly combining edge analytics and cloud-based processing, sensor networks in predictive maintenance can provide a holistic and proactive approach to asset management, empowering manufacturers to make data-driven decisions and maximize operational efficiency.

Securing Sensor Networks for Predictive Maintenance

As sensor networks become increasingly integral to industrial operations, the security of these systems has become a critical concern. Implementing robust security measures is essential to protect against cyber threats, ensure data integrity, and safeguard the reliability of predictive maintenance systems.

Authentication and Authorization: Sensor nodes and edge devices must undergo secure authentication to verify their identity and authorization to access and interact with the network. This can be achieved through certificate-based authentication, cryptographic keys, or multi-factor authentication methods.

Encryption and Data Protection: Sensitive sensor data and communication channels must be encrypted to prevent unauthorized access and data tampering. End-to-end encryption, secure protocols (such as TLS/SSL), and secure gateways can help mitigate the risk of data breaches and ensure the confidentiality of critical information.

Secure Firmware and Software Updates: Regular firmware and software updates are crucial to address vulnerabilities and security threats that may emerge over time. Mechanisms for secure over-the-air (OTA) updates and version control can help maintain the integrity and resilience of the sensor network infrastructure.

Network Segmentation and Zoning: Dividing the sensor network into logical zones or segments can limit the attack surface and contain the impact of potential security breaches. This approach, combined with access control lists and firewalls, can enhance the overall security posture of the predictive maintenance system.

Monitoring and Incident Response: Continuous monitoring of the sensor network, anomaly detection, and incident response procedures are essential to identify, investigate, and mitigate any security incidents or cyberattacks in a timely manner.

By addressing these security considerations, manufacturers can build resilient and trustworthy sensor networks that support their predictive maintenance initiatives while safeguarding their critical assets and operational data.

Energy Management Strategies for Sensor Networks

The energy efficiency of sensor networks is a crucial factor in the success of predictive maintenance applications, particularly in remote or distributed manufacturing environments where power availability and accessibility can be a challenge.

Low-Power Sensor Designs: Advancements in sensor technology and microcontroller design have led to the development of low-power sensor nodes that can operate for extended periods on battery power or energy harvesting solutions, reducing the need for frequent battery replacements or wired power connections.

Duty Cycling and Sleep Modes: Sensor nodes can be programmed to cycle between active and sleep modes, reducing their power consumption during periods of inactivity. This duty cycling approach, combined with adaptive sampling rates, can significantly extend the battery life of sensor nodes while maintaining the necessary data collection for predictive maintenance.

Energy Harvesting and Storage: Energy harvesting technologies, such as solar panels, piezoelectric materials, or thermoelectric generators, can be integrated into sensor nodes to supplement or replace battery power, enabling self-powered and sustainable sensor network deployments.

Distributed Power Management: In decentralized or distributed sensor network architectures, edge gateways and intermediate nodes can play a crucial role in power management, load balancing, and energy optimization across the entire network, ensuring efficient utilization of available power resources.

Predictive Maintenance and Energy Optimization: By leveraging the predictive maintenance capabilities of sensor networks, manufacturers can optimize energy consumption by anticipating and addressing potential equipment failures or inefficiencies before they occur, leading to reduced energy waste and improved operational efficiency.

Integrating low-power sensor designs, energy harvesting, and distributed power management strategies can help create energy-efficient sensor networks that support the long-term sustainability and reliability of predictive maintenance initiatives in manufacturing environments.

Conclusion: The Future of Sensor Networks in Predictive Maintenance

The intersection of sensor networks, IoT, and predictive analytics has transformed the way manufacturers approach asset management and maintenance. By leveraging the power of distributed sensor data, manufacturers can now anticipate and prevent equipment failures, optimize maintenance schedules, and improve overall operational efficiency.

As sensor network technologies continue to evolve, we can expect to see further advancements in areas such as edge computing, wireless connectivity, energy efficiency, and security, all of which will play a crucial role in shaping the future of predictive maintenance in the manufacturing industry.

To explore the latest developments and stay ahead of the curve, we encourage you to visit sensor-networks.org, a comprehensive resource for all things related to sensor networks, IoT, and their applications in various industries.