In the rapidly evolving world of sensor networks and the Internet of Things (IoT), the ability to anticipate and mitigate equipment failures has become a critical priority for industries across the spectrum. Predictive maintenance, a well-established practice in sectors such as manufacturing, energy, and transportation, has emerged as a transformative solution, leveraging the power of machine learning and data analytics to optimize equipment performance and reduce costly downtime.

The Evolution of Predictive Maintenance

Predictive maintenance has its roots in the aviation and military sectors of the 1940s and 1950s, where monitoring systems were used to detect and predict potential failures in aircraft engines. Over the decades, as computers and sensors became more prevalent, industries began to explore ways to leverage the available data to predict equipment failure and optimize maintenance schedules.

In the 1990s and 2000s, predictive maintenance gained widespread attention, with the rise of IoT and increased connectivity of industrial equipment driving the development of more sophisticated solutions. Real-time data, machine learning, and advanced predictive analytics became the foundation for predicting potential issues, scheduling maintenance tasks more efficiently, and reducing the likelihood of unplanned downtime and costly repairs.

The Power of Sensor Networks

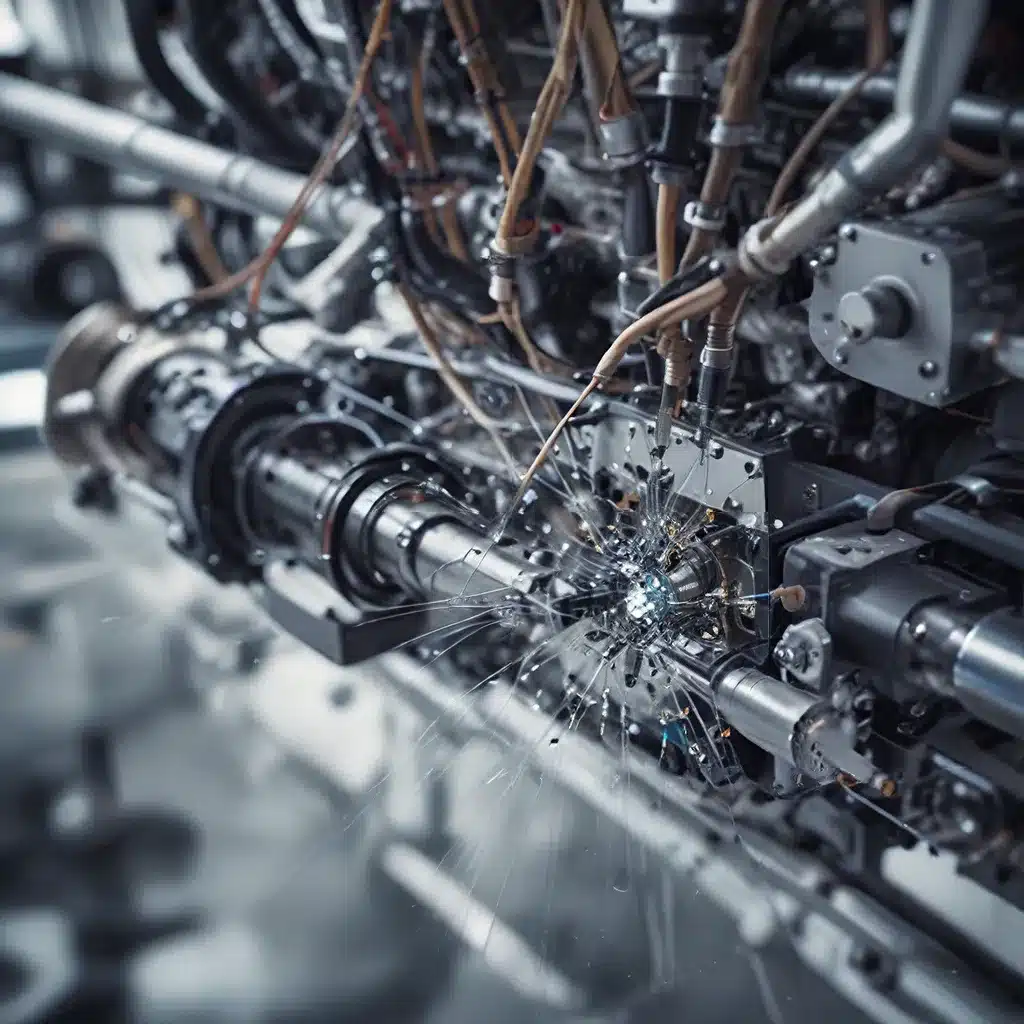

At the heart of predictive maintenance lies the sensor network, a critical component that collects the real-time data necessary for analysis and decision-making. Sensor nodes deployed within machines or operating environments gather crucial information, such as temperature, pressure, and vibration, providing the insights needed to assess equipment health and anticipate potential failures.

The mesh sensor network topology, where interconnected sensor nodes relay data to a central hub or collection point, facilitates the transmission of information across multiple locations, enabling a comprehensive view of an entire system’s performance.

Machine Learning and Predictive Analytics

Predictive maintenance solutions leverage machine learning and advanced data analytics to process the sensor data, identifying patterns, anomalies, and trends that indicate potential equipment failure. By applying sophisticated algorithms and models to the collected information, these systems can accurately predict when maintenance is required, optimize schedules, and minimize the risk of unplanned downtime.

Condition monitoring techniques, such as vibration analysis, thermography, oil analysis, and acoustic emission testing, play a crucial role in assessing the health of machinery, providing the necessary data for predictive maintenance algorithms to operate effectively.

IoT and Connectivity Solutions

The rise of IoT has further revolutionized the landscape of predictive maintenance, enabling the seamless integration of sensor networks, communication protocols, and cloud-based platforms. IoT communication-as-a-service solutions, such as SIM-based low-power wide-area (LPWA) networks and MQTT-SN protocols, have significantly lowered the cost of IoT deployments, making predictive maintenance more accessible to a wider range of industries.

Furthermore, the introduction of advanced wireless technologies, like Wi-Fi 6 and LTE-M/NB-IoT, has enhanced the connectivity and reliability of sensor networks, ensuring the timely transmission of critical data for real-time monitoring and analysis.

The Business Impact of Predictive Maintenance

Predictive maintenance has not only transformed the way industries maintain their equipment but has also opened the door to innovative business models. By offering “availability as a service,” companies can shift their focus from simply selling motors or machinery to ensuring continuous machine rotation and reliable performance.

This strategic shift goes beyond mere transactions, fostering lasting partnerships between service providers and customers. By improving visibility, optimizing maintenance, and ensuring sustainable machine availability, predictive maintenance solutions have become a powerful enabler of business transformation and competitive advantage.

Addressing Security Challenges

As with any connected system, the implementation of predictive maintenance in sensor networks raises important security considerations. Cybersecurity has become a critical concern, as the integration of IoT devices and cloud-based platforms creates new attack vectors that must be addressed.

Robust security protocols, encryption techniques, and access control mechanisms are essential to protect the integrity of sensor data, prevent unauthorized access, and safeguard the overall system against malicious attacks. Continuously monitoring for potential threats and implementing proactive security measures is paramount to ensure the reliability and trustworthiness of predictive maintenance solutions.

Driving Energy-Efficient Designs

Alongside security, the energy efficiency of sensor networks is a crucial factor in the successful deployment of predictive maintenance systems. Sensor nodes, which are often located in remote or hard-to-reach areas, must be designed to operate with minimal power consumption to ensure long-term reliability and reduce maintenance costs.

Advancements in low-power wireless technologies, such as Bluetooth Low Energy (BLE) and LoRaWAN, have enabled the development of energy-efficient sensor nodes that can operate for extended periods on battery power, reducing the need for frequent battery replacements or recharging.

Furthermore, the integration of energy harvesting techniques, such as solar or vibration-based power generation, can further enhance the sustainability and longevity of sensor networks, making predictive maintenance solutions more accessible and cost-effective to deploy in a wide range of applications.

The Future of Predictive Maintenance

As the sensor network and IoT landscape continues to evolve, the role of predictive maintenance in shaping the future of industrial automation and smart infrastructure is undeniable. With advancements in machine learning, data analytics, and connectivity solutions, the potential for predictive maintenance to drive groundbreaking innovations across various sectors is vast and compelling.

From optimizing the performance of wind turbines and ensuring the reliability of critical infrastructure to enhancing the efficiency of manufacturing processes and reducing the environmental impact of industrial operations, the impact of predictive maintenance powered by sensor networks and IoT is far-reaching and transformative.

By embracing these technologies and leveraging the power of machine learning, industries can unlock new levels of operational excellence, unlock cost savings, and pave the way for a more sustainable and resilient future. As the world continues to digitize and interconnect, the importance of predictive maintenance will only continue to grow, cementing its place as a critical enabler of industrial innovation and transformation.

Explore the sensor networks organization website to dive deeper into the latest advancements and applications of this exciting field.