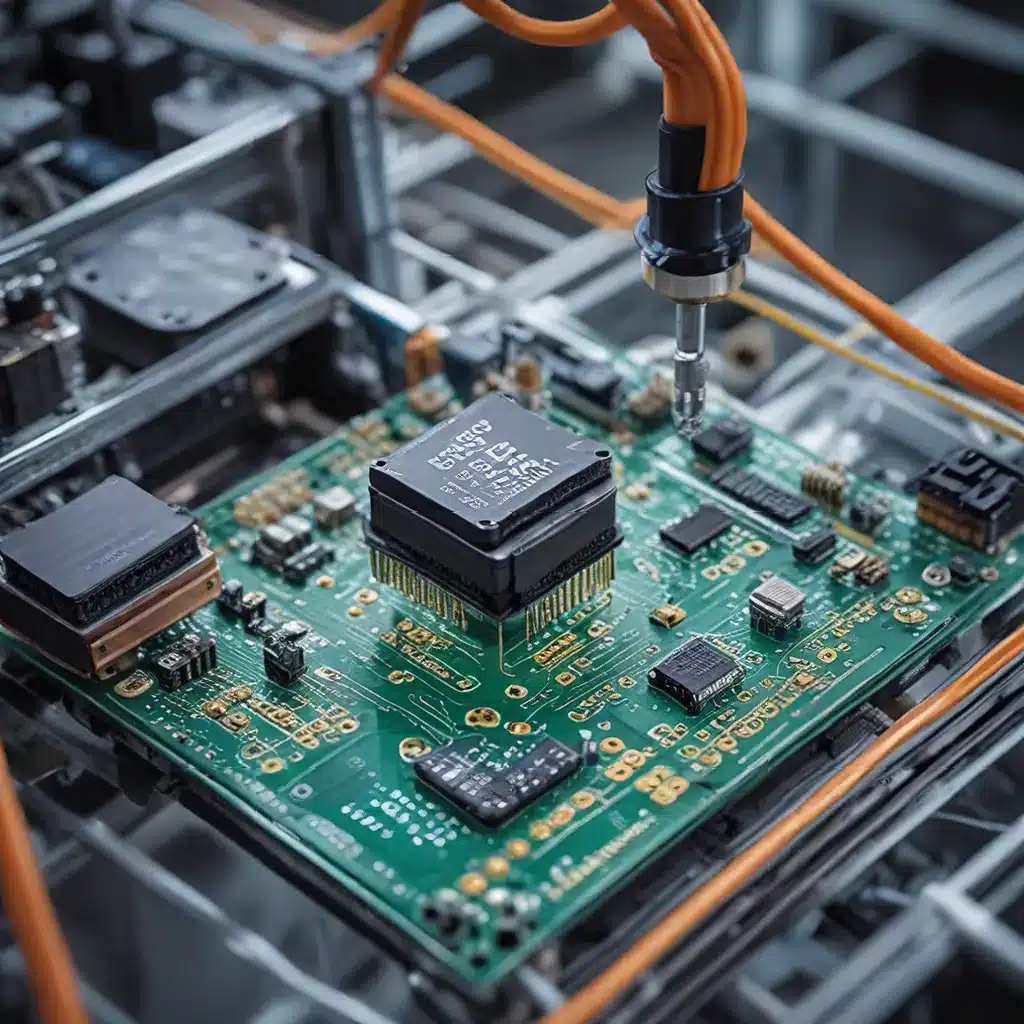

In today’s rapidly evolving manufacturing landscape, the integration of sensor networks and Internet of Things (IoT) technologies is transforming the industry, powering a massive digital transformation. From manufacturing automation using robotics and cobotics (human-robot collaboration) to predicting equipment failure on the factory floor and tracking assets in a warehouse, the industrial IoT is at the center of the future of manufacturing.

Unlocking the Potential of Sensor Networks in Manufacturing

Sensor networks are the backbone of the industrial IoT revolution, enabling manufacturers to gather vast amounts of real-time data from across their operations. These interconnected sensors can be deployed on production equipment, throughout the supply chain, and even on finished products, providing a comprehensive view of the manufacturing ecosystem.

Leveraging sensor networks, manufacturers can gain unprecedented insights into their processes, enabling them to optimize production, improve quality, and enhance operational efficiency. By monitoring critical parameters such as temperature, pressure, vibration, and energy consumption, sensor networks can detect anomalies, predict maintenance needs, and identify opportunities for process improvements.

Moreover, the data collected by sensor networks can be integrated with advanced analytics and artificial intelligence (AI) algorithms to uncover hidden patterns and trends. This powerful combination allows manufacturers to make data-driven decisions, automate processes, and anticipate and mitigate potential issues before they arise.

Enhancing Manufacturing Efficiency through IoT Applications

The integration of sensor networks and IoT technologies has opened up a vast array of applications that are revolutionizing the manufacturing industry. Let’s explore some of the key use cases:

Production Optimization

Sensor networks can provide real-time visibility into the production line, enabling manufacturers to identify bottlenecks, optimize workflows, and enhance overall equipment effectiveness (OEE). By continuously monitoring key performance indicators (KPIs) such as cycle time, yield, and downtime, manufacturers can make data-driven adjustments to improve productivity and reduce waste.

Predictive Maintenance

Sensor-enabled predictive maintenance is a game-changer in the manufacturing sector. By continuously monitoring the health and performance of production equipment, sensor networks can detect early warning signs of potential failures, allowing manufacturers to proactively schedule maintenance and minimize unplanned downtime. This predictive approach not only improves equipment reliability but also extends the lifespan of critical assets.

Supply Chain Visibility

Sensor networks can be integrated throughout the supply chain, providing end-to-end visibility and real-time tracking of raw materials, work-in-progress, and finished goods. This enhanced visibility allows manufacturers to optimize inventory levels, streamline logistics, and respond quickly to changes in demand or disruptions in the supply chain.

Quality Assurance

Sensor-enabled quality assurance is a powerful tool in the manufacturing environment. By monitoring critical quality parameters throughout the production process, manufacturers can detect and address quality issues in real-time, ensuring consistent product quality and reducing the likelihood of costly recalls or rework.

Asset Tracking

Sensor networks can be used to track the location and status of manufacturing assets, such as equipment, tools, and materials. This asset tracking capability enables manufacturers to improve inventory management, optimize resource utilization, and enhance overall asset visibility.

Addressing the Challenges of Sensor Network Security and Energy Management

As the adoption of sensor networks and IoT technologies in manufacturing continues to grow, it is essential to address the challenges of security and energy management to ensure the long-term sustainability and reliability of these systems.

Sensor Network Security

The integration of sensor networks and IoT devices in manufacturing environments introduces new security risks, such as unauthorized access, data breaches, and potential disruption of critical operations. Manufacturers must prioritize the implementation of robust security protocols, including encryption, access controls, and network segmentation, to protect their sensitive data and operational integrity.

Emerging technologies like blockchain are also being explored to enhance the security of sensor networks, providing a decentralized and tamper-resistant platform for data management and device authentication.

Energy-Efficient Sensor Network Design

Sensor networks in manufacturing often require low-power operation due to the remote or distributed nature of the deployment. Manufacturers must focus on energy-efficient sensor network design to ensure the long-term sustainability of their IoT infrastructure.

Strategies such as duty-cycling, energy harvesting, and power-aware communication protocols can help extend the battery life of sensor nodes and reduce the overall energy consumption of the network. Additionally, the adoption of low-power wireless technologies, such as Bluetooth Low Energy (BLE) and LoRaWAN, can further optimize the energy efficiency of sensor networks in manufacturing environments.

Embracing the Future of Sensor Networks in Manufacturing

As the digital transformation of the manufacturing industry continues to accelerate, the integration of sensor networks and IoT technologies will play a pivotal role in driving precision manufacturing, improving quality, productivity, and operational efficiency.

By harnessing the power of sensor-based data and advanced analytics, manufacturers can unlock new levels of operational visibility, decision-making capabilities, and proactive maintenance strategies. Moreover, the continued advancements in sensor network security and energy-efficient designs will ensure the long-term sustainability and reliability of these critical systems.

As you explore the opportunities presented by sensor networks and IoT in manufacturing, consider visiting sensor-networks.org to stay informed on the latest trends, technologies, and best practices shaping the future of this dynamic industry.