Transforming the Supply Chain with Artificial Intelligence

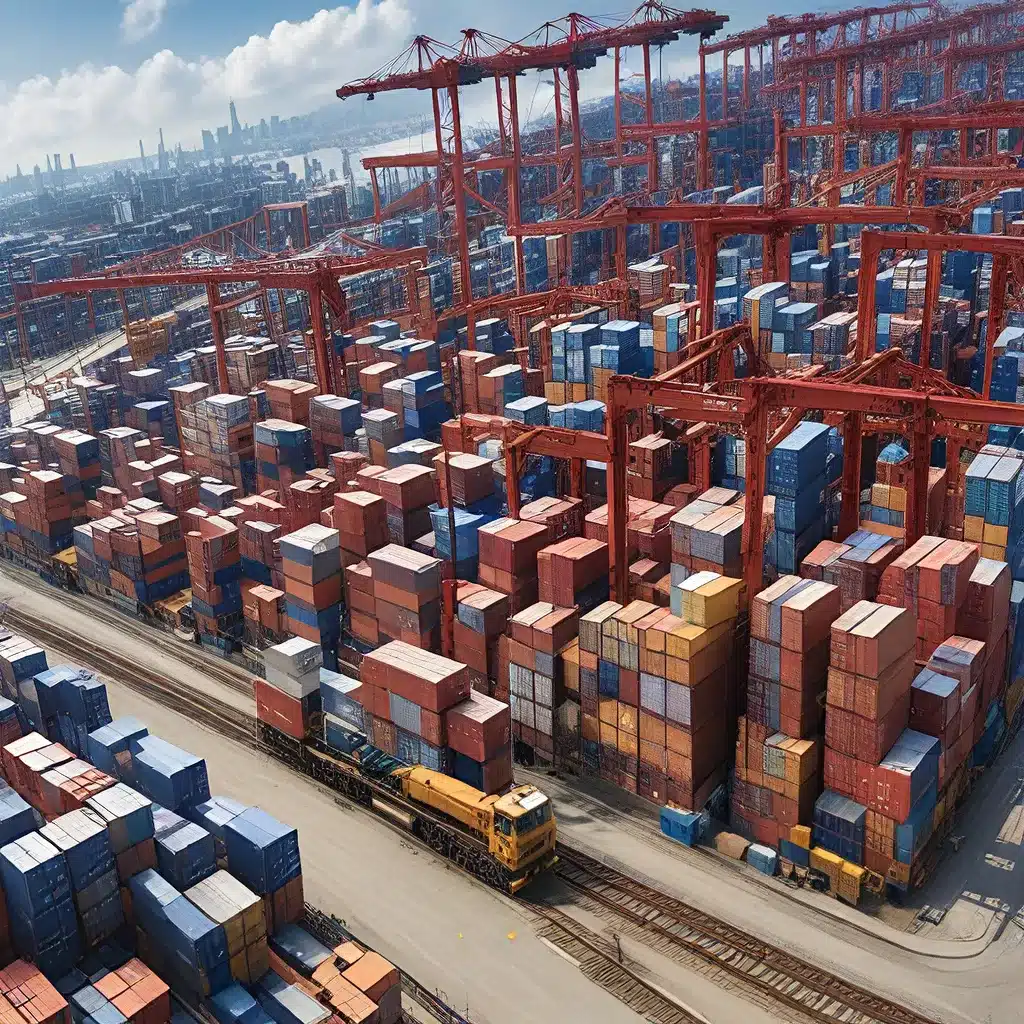

In today’s rapidly evolving business landscape, supply chain optimization has become a critical factor for success. The increasing complexity of global supply networks, coupled with volatile market conditions and unexpected disruptions, has made it imperative for organizations to seek innovative solutions. Artificial Intelligence (AI) has emerged as a game-changing technology in this arena, offering unprecedented opportunities to enhance efficiency, improve resilience, and drive competitive advantage.

At Sensor-Networks.org, we are at the forefront of leveraging AI to revolutionize supply chain management. Let’s delve into the transformative impact of AI on various aspects of supply chain optimization.

1. Advanced Demand Forecasting

One of the most significant applications of AI in supply chain management is in demand forecasting. Traditional forecasting methods often fall short in capturing the nuances of market dynamics, leading to inefficiencies in inventory management. AI and machine learning (ML) algorithms, however, can analyze vast amounts of data from diverse sources to generate highly accurate demand predictions.

These AI-powered systems can process historical sales data, seasonal trends, economic indicators, social media sentiment, and even weather patterns to forecast demand with remarkable precision. For instance, a study by McKinsey found that AI-driven forecasting can reduce errors by up to 50% and lost sales by up to 65%.

The implications are profound: optimized inventory levels, reduced carrying costs, minimized stockouts, and improved customer satisfaction. Retailers and manufacturers can make more informed decisions about production schedules, procurement, and distribution, leading to a more agile and responsive supply chain.

2. Real-Time Visibility and Intelligent Tracking

AI combined with Internet of Things (IoT) technologies is revolutionizing supply chain visibility. Smart sensors and AI-powered analytics provide real-time insights into the location, condition, and status of goods as they move through the supply chain.

This enhanced visibility allows companies to:

– Track shipments with unprecedented accuracy

– Monitor environmental conditions for sensitive goods

– Identify bottlenecks and inefficiencies in real-time

– Predict and mitigate potential disruptions before they escalate

For example, AI algorithms can analyze data from IoT sensors to detect anomalies that might indicate a problem, such as unexpected temperature fluctuations in a refrigerated container. This allows for proactive intervention, potentially saving millions in spoiled goods.

3. Intelligent Routing and Logistics Optimization

AI is transforming logistics operations by optimizing routes and streamlining transportation networks. Machine learning algorithms can analyze multiple variables – including traffic patterns, weather conditions, fuel costs, and delivery time windows – to determine the most efficient routes and modes of transport.

These systems can dynamically adjust routes in real-time based on changing conditions, ensuring timely deliveries while minimizing costs. A study by IBM found that AI-powered route optimization can reduce logistics costs by up to 15% and improve delivery times by up to 25%.

Moreover, AI can optimize warehouse operations through intelligent inventory placement and automated picking systems, further enhancing efficiency in the supply chain.

4. Supplier Selection and Risk Management

AI is proving invaluable in supplier relationship management and risk mitigation. By analyzing vast amounts of data – including supplier performance metrics, financial indicators, geopolitical factors, and even news sentiment – AI systems can:

– Identify the most reliable and cost-effective suppliers

– Predict potential supply chain disruptions

– Recommend alternative sourcing strategies

– Optimize contract negotiations

This data-driven approach to supplier management not only improves operational efficiency but also significantly enhances supply chain resilience. Companies can proactively address potential risks and quickly adapt to changing market conditions.

5. Predictive Maintenance and Quality Control

AI-powered predictive maintenance is revolutionizing asset management in the supply chain. By analyzing sensor data from equipment and facilities, AI algorithms can predict when maintenance will be needed, allowing companies to schedule repairs before breakdowns occur. This approach minimizes downtime, extends asset lifecycles, and reduces maintenance costs.

In quality control, computer vision and machine learning algorithms can detect defects and inconsistencies far more quickly and accurately than human inspectors. This not only improves product quality but also reduces waste and enhances overall operational efficiency.

6. Sustainable Supply Chain Management

As sustainability becomes increasingly important, AI is playing a crucial role in helping companies optimize their supply chains for environmental impact. AI algorithms can analyze complex data sets to:

– Optimize transportation routes for reduced carbon emissions

– Identify opportunities for waste reduction and circular economy practices

– Assess suppliers based on sustainability metrics

– Model the environmental impact of different supply chain configurations

By leveraging AI for sustainability, companies can not only reduce their environmental footprint but also often realize cost savings and improved brand reputation.

The Road Ahead: Challenges and Opportunities

While the potential of AI in supply chain optimization is immense, its implementation is not without challenges. Organizations must address issues such as:

– Data quality and integration: AI systems require large amounts of clean, integrated data to function effectively.

– Skill gaps: There’s a growing need for professionals who understand both supply chain management and AI technologies.

– Ethical considerations: As AI becomes more prevalent, issues of data privacy, algorithmic bias, and job displacement must be carefully addressed.

– Change management: Implementing AI often requires significant changes to processes and organizational culture.

Despite these challenges, the future of AI in supply chain management is bright. We’re moving towards a future of autonomous supply chains, where AI systems can make complex decisions and self-optimize with minimal human intervention. Digital twins powered by AI will allow companies to simulate and stress-test their supply chains in virtual environments before implementing changes in the real world.

At Sensor-Networks.org, we’re committed to helping organizations navigate this exciting frontier. By combining cutting-edge AI technologies with deep supply chain expertise, we’re enabling our clients to build more intelligent, efficient, and resilient supply networks.

As we look to the future, one thing is clear: AI will continue to be a driving force in supply chain innovation. Organizations that successfully leverage these technologies will be well-positioned to thrive in an increasingly complex and competitive global marketplace. We’d love to hear your thoughts on the role of AI in supply chain optimization. What opportunities or challenges do you see in your industry? How is your organization leveraging AI to enhance supply chain performance? Let’s continue this important conversation in the comments below.